Leather is a highly variable product due to the inconsistency in size, shape, and quality. These variables are also what makes leather a really unique product to work with, but can also lead to large waste factors and increasing cost for a company.

In order to reduce variability in leather consumption/usage and more accurately track how much leather is on hand, I separate the two ways the leather presents its self as a raw materiel in a typical production house:

- Whole hide (untouched from the tannery)

- Scrap or drop off from blocking

Having two high level buckets makes it easier to understand how usable leather square footage you have on hand is. Think about it this way, if you have 1000 sq. ft. of leather on hand but it’s all in 1 sq. ft. pieces, the belt demand for leather is 500 sq. ft. total but each individual belt requires a 48″ by 1″ piece of leather. You can make exactly 0 belts with the leather you have on hand in it’s current form.

With the buckets above, we create visibility on what form the leather is in, which will help eliminate orders issued for unusable raw material.

The first step in creating the whole hide and scrap locations is to do a cycle count on the leather that’s on hand. Whole hides come in with the size of the hide printed on the flesh side, which can be added up to get an accurate count of how much square footage is available in whole hide form. Getting an accurate count of scrap leather (the drop off leather after the initial cuts of the whole hide) is much more difficult. The easiest way to tackle this with some level of accuracy is the following:

- Make sure all of the leather types are separated out into their own storage bins

- grab a weight for each of the empty bins used to store the leather

- Cut samples of 1 sq. ft. of all of the different leather types and measure the weight

- if you have a whole hide available for all the different leather scrap, grab a weight for these and calculate the lbs/sq. ft.

- Weigh the bins each of the different leather types

- subtract out the weight of the empty bins from the total weight

- use the lbs/sq. ft. you calculated from step 2 to identify an approximate number of square footage there is in each bin of scrap.

- Please note that Leather has a high variability in density which makes the weight inconsistent on a square footage basis, if you have enough samples in weight from step 2, you can build out a distribution of how much leather you have based on weight and use the average for the sample. I have found there is about a 30% swing in square footage when using weight to identify square footage and in order to avoid over reporting leather available in scrap, I always use the lower quantile of leather square footage available based on weight.

- Use the attached tracking sheet when you pull leather from the whole hide location for an order

- the tracking sheet is standardized so that you mark down

- the grade of the hide

- the size of the hide

- the dimensions of the cut you took out of the hide

- the tracking sheet is standardized so that you mark down

- Place the drop off into your dedicated leather bin based on the type of leather

- Use the attached calculator to tell you how much leather to consume out of the whole hide location and move into the scrap location.

- the calculator will roll up the number of whole hides used and their size, the dimensions of the leather cut out, and the remainder available to be placed into the scrap location

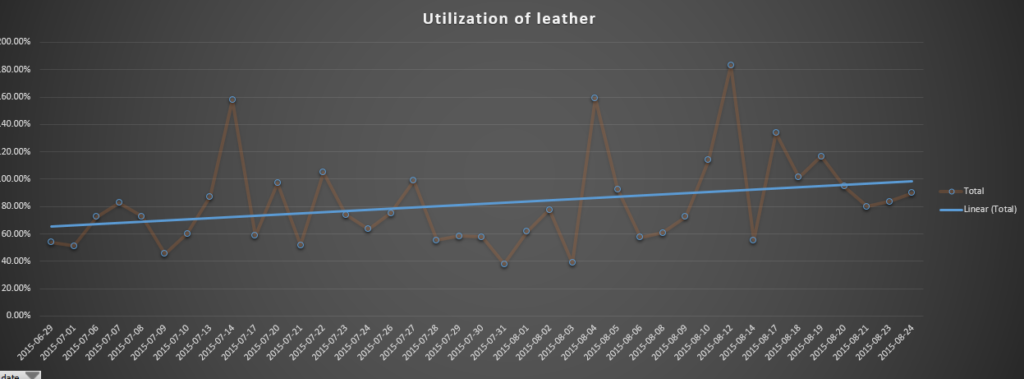

Doing this simple bucketing technique, Filson was able to improve their on hand accuracy of leather from 47% – 80% and also improve the yield on leather (due to better oversight on how much leather is being used from the whole hide location) used on the classic briefcase (70256) from 67% to 88% leather utilization, which can be seen in the graph below:

Leather Consumption calculator